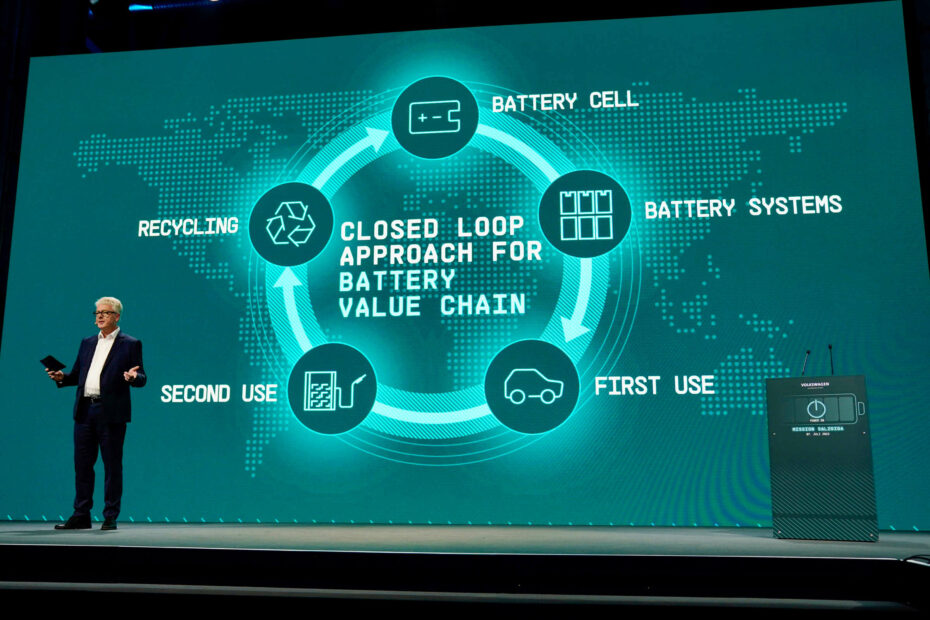

Volkswagen’s Strategy for Battery Cell Production

Volkswagen plans to invest in mines to reduce battery cell costs, meet half of its own demand, and sell to third-party customers, according to the carmaker’s board member in charge of technology. This move is in line with the broader trend of automakers seeking greater control over parts of the supply chain, from energy generation to raw material sourcing, as they compete for scarce resources needed to meet electrification targets.

PowerCo: Aiming to Become a Global Battery Supplier

Volkswagen’s battery unit, PowerCo, aims to become a global battery supplier and meet half of the automaker’s demand with plants primarily in Europe and North America. PowerCo will begin by supplying cells to Ford for the 1.2 million vehicles the U.S. carmaker is building in Europe on Volkswagen’s electric MEB platform. To address the bottleneck in raw materials, Volkswagen plans to invest directly in mines, with partnerships underway in Canada for its first North American battery plant.

Ambitious Roadmap for Battery Production and Sales

PowerCo, established last year, targets over €20 billion in annual sales by 2030. The unit faces an ambitious roadmap, with production starting in 2025 at its Salzgitter, Germany plant, 2026 in Valencia, Spain, and 2027 in Ontario, Canada. Volkswagen remains confident in its ability to expand quickly, recognizing the importance of reducing battery costs to produce affordable electric vehicles (EVs).

Competing with Tesla and BYD in the EV Market

Acquiring batteries at a reasonable cost is a challenge for carmakers like Volkswagen, Tesla, and Stellantis, as they strive to make EVs more affordable. Only Tesla has committed more investment into battery production than Volkswagen, although the U.S. EV maker is also struggling to increase production and is seeking help from Asian suppliers. Volkswagen faces stiff competition from China’s BYD, which leads the affordable EV race and has outsold the German automaker twice in four months in China.

Reducing Costs and Securing Raw Material Supply

Of Volkswagen’s €180 billion five-year spending plan, up to €15 billion is designated for its three announced battery plants and some raw material sourcing. The automaker has secured raw material supply until 2026 and will decide in the next few months how to meet its demand thereafter. Volkswagen has also ordered $14 billion in batteries from Northvolt’s Swedish plant. Reducing battery costs remains a challenge, and Volkswagen aims to use all available instruments with PowerCo to address this issue.

situs togel

toto slot

rtp slot

situs toto

bo togel

situs toto

situs toto

situs togel

bo togel

pam4d

situs togel

toto togel

situs togel

situs togel

bento4d

situs togel

bento4d

situs togel

pam4d

situs toto

pam4d

daftar pam4d

daftar pam4d

login bento4d

cerutu4d

cerutu4d

cerutu4d

situs toto

situs togel

situs toto

situs toto

situs togel

situs toto

situs toto

situs togel

situs togel

toto togel

situs toto

situs togel

situs togel resmi

toto slot

situs toto

situs togel

situs toto

situs togel

situs toto

situs toto

situs togel

cerutu4d

situs toto

cerutu4d

situs toto

gimbal 4d

daftar gimbal4d

gimbal4d

toto slot

situs toto

situs toto

toto slot

situs toto

situs toto

toto togel

toto slot

situs togel

live casino

toto slot

toto togel

bandar togel

situs toto

situs toto

situs togel

situs toto

situs toto

bakautoto

situs bandar togel

bakautoto situs resmi toto togel

bakautoto situs toto togel terpercaya 2024

monperatoto

monperatoto

monperatoto

monperatoto

monperatoto

monperatoto

situs togel

situs toto

situs toto

situs toto

situs toto

bo toto pulsa

bo toto

bo toto pulsa

bo togel

bo togel

bo togel

bo togel

cerutu4d

bo togel

bo toto

situs togel

situs togel

situs toto

situs toto

situs togel

bakautoto

situs togel

bakautoto

situs togel

situs toto

situs togel

bo togel

situs togel

bandar toto macau

togel pulsa

bo togel

Daftar Situs Toto

situs toto

situs toto

situs toto

situs toto

situs toto

situs togel

situs togel

situs toto

situs toto

togel

situs toto

situs lotre

situs togel

bakautoto

togel resmi

bakautoto

bakautoto

bakautoto

bakautoto

situs toto

bento4d

bento4d

situs toto

jacktoto

situs toto

situs toto

pam4d

bo togel

situs toto

situs toto

situs toto

bo togel

bandar togel

situs togel

jacktoto

monperatoto

monperatoto

monperatoto

monperatoto

monperatoto

data macau

slot gacor hari ini

situs toto

situs toto

situs toto

togel online

bandar togel online

bandar toto macau

bandar togel

bo togel

situs togel

situs toto

bo togel

situs toto

bo togel

bet togel

situs toto

jacktoto

bo togel

situs togel

situs togel

situs togel

situs togel

bo togel

situs toto

rimbabola

agen toto togel

situs togel

situs togel

situs toto

situs togel

situs togel

situs togel online

situs toto

bo toto

situs toto

bandar toto macau

situs toto

situs toto macau

togel dana

situs togel

situs togel

situs toto

togel

situs togel online

situs toto

cabe4d

monperatoto

monperatoto

monperatoto

monperatoto

monperatoto

data macau

monperatoto

slot gacor hari ini

situs toto

situs toto

toto togel

situs toto

link togel

rimbabola

situs toto

situs toto togel

slot gacor

bento4d

togel pulsa

situs toto

situs toto

situs toto

situs toto

situs toto

bento4d

bo toto

cabe4d

bo toto

jacktoto

situs toto

situs deposit pulsa

cerutu4d

cerutu4d

rimbabola

situs toto macau

situs toto macau

situs togel online

situs toto

situs togel terpercaya

situs toto

rtp

situs togel

situs togel

situs toto

situs togel

bandar togel

situs togel

jacktoto

situs toto

situs toto

situs slot gacor

situs togel

situs toto

bo togel

situs togel

situs toto

situs toto

situs toto

situs toto

situs togel

bo togel

bakautoto

bo togel

bakautoto

bet togel

situs togel

situs togel online

situs toto

bo togel

bandar togel

situs togel

situs toto

bo togel

rimbabola

situs togel

bo togel

situs toto

togel online

situs toto

bandar togel

bo togel

bandar totomacau

bo toto pulsa

cerutu4d

situs togel

situs togel

situs togel

situs toto

situs toto

situs toto

link togel

togel online

situs togel

situs togel4d

bo togel terpercaya

situs toto

situs toto

pam4d

bakautoto

situs togel

situs togel

bo togel

bo toto

situs toto

bo toto

situs bandar togel

situs toto

situs togel

bo togel

bandar togel resmi

situs toto

cerutu4d

situs togel

situs toto togel

situs togel

bo togel

agen togel

situs togel

situs togel

situs toto

situs toto

situs toto

bo togel

cabe4d

situs togel

situs toto

situs togel

situs togel

situs togel

situs toto

cabe4d

situs toto

bandar togel

situs toto

cabe4d

situs toto

PAM4D

PAM4D

PAM4D

rimbabola

PAM4D

gimbal4d

situs toto

https://iaida.ac.id/bandar

https://ak.poliupg.ac.id/ngacor/

agen togel

cabe4d

cabe4d

bandar togel

bo togel

situs togel

pam4d

situs togel

agen toto

situs togel

bo togel

https://disdukcapil.salatiga.go.id/ngacor/

situs togel

bo toto

situs toto

situs toto

bandar toto macau

situs toto

situs toto

cabe4d

situs togel

situs togel

jacktoto

pam4d

situs togel

situs toto

situs toto

bandar togel

bandar togel

situs toto

situs togel

pam4d

situs toto

bandar togel

bandar togel

situs togel

situs toto

situs toto

cabe4d

situs togel

situs togel

situs toto

situs slot gacor

situs toto

situs togel

situs togel

cabe4d

situs toto slot

situs toto

situs toto

bandar toto macau

rtp live

situs togel

situs togel

situs togel resmi

situs toto

toto macau 4d

toto togel

situs toto

togel terpercaya

bandar toto macau

slot gacor

toto slot

toto slot

https://caselledental.com/

situs togel

situs toto

situs togel

situs togel

situs toto

bandar togel

situs togel

situs toto

cerutu4d

situs toto

jacktoto

situs togel

cerutu4d

cerutu4d

cerutu4d

situs togel

situs togel

situs toto

situs toto

situs togel

situs togel

cerutu 4d

cerutu 4d

cerutu 4d

situs toto

bandar togel

situs toto

situs toto

situs toto

cerutu 4d

situs toto

situs togel

situs togel

toto togel

situs toto

situs togel

situs togel

toto togel

bo toto

situs toto

situs togel terpercaya

cabe4d

cerutu 4d

situs toto

situs toto

bo toto

togel resmi

togel terpercaya

bo toto

situs togel resmi

situs togel resmi

bandar togel

situs togel

bo togel

cabe4d

cabe4d

bento4d

situs togel

jacktoto

jacktoto

bento4d

bento4d

situs togel

situs togel

situs toto

situs togel

situs toto

situs togel

jacktoto

link togel

situs toto macau

jacktoto

bo togel

toto slot

https://www.pilgrimagetour.in/-/

slot gacor

situs toto

slot gacor

slot gacor

rtp slot

bandar togel

bo toto

toto togel

situs toto

toto slot

situs togel

bo togel

bandar togel

jacktoto

situs toto

situs togel

bandar togel terpercaya

situs toto

situs toto

https://mikrotik.itpln.ac.id/wp-content/uploads/

situs toto

situs toto

monperatoto

situs toto

bo togel

situs togel

situs toto

agen togel

situs togel

bento4d

bo togel

bo togel

situs toto

bo togel

situs togel

situs toto

situs toto

jacktoto

jacktoto

bo togel

situs toto

slot gacor

jacktoto

bo toto togel

slot gacor

situs toto

bandar toto macau

situs toto

https://smkn2depoksleman.sch.id/

https://greenwise.co.id/

https://e-journal.rsudbandungkiwari.or.id/

https://labor.rsudbandungkiwari.or.id/

https://team.rsudbandungkiwari.or.id/

togel online

bo togel

bo togel

![LOGO [återskapat] LOGO [återskapat]](https://batteryjuniors.com/wp-content/uploads/elementor/thumbs/LOGO-återskapat-ozpr6tyjh3va1ifcopltktksqownqc64mplxytts9k.png)